Q: In what year was your company established?

A: Independent Maintenance Services started in 2011

Q: How many employees did you employ when you first started the business?

A: 2 people.

Q: How many do you currently employ?

A: We currently have 8 staff employed directly and the number can increase to approximately 20 staff depending on the specific project requirements.

Q: Do you operate from a number of locations in Australia?

A: Our main office is located in Melbourne, however we also operate from offices in Gladstone and Port Hedland.

Q: What is your core business? (e.g. blasting and painting, rubber lining, waterjetting, laminating, insulation, flooring etc.)

A: We specialise in Rope Access providing Industrial Surface Preparation and Coatings Application. We also provide general maintenance and inspection services. Plus all our team at IMS are Rope Access and Confined Space Entry and Rescue trained which allows us to perform tasks in areas that are remote and difficult to access.

Q: What markets do you cover with your products or services? eg: oil & gas, marine, chemical process, general fabrication, tank lining, offshore etc.

A: We have been servicing the Oil and Gas Industry on and offshore, predominantly and we also have broad experience in operating within urban environments such as: high rise buildings, bridges and structures including wind towers.

Q: Is the business yard based, site based or both?

A: Because of the specifics of our services (Rope Access) the majority of our projects are site based, however we have the capability to provide surface preparation and coatings on piping, vessels etc. from the yard in Melbourne

Q: What is your monthly capacity or tonnage that you can blast and prime?

A: This can vary depending on the size of the project, however when it comes to Rope Access methods, it is not about meterage and tonnage but about accessing the work location safely using non-conventional ways. Our highly qualified team are capable of meeting the majority of our Clients requirements.

Q: Do you offer any specialty services outside your core business? (eg. primary yard based but will do site touch up etc.)

A: As mentioned above our team are Rope Access, Confined Space Entry and Rescue trained which enables our team to manage and control the rescue scenarios for activities on Heights and Confined Spaces. We also offer jacket protection using Stopaq, among other protective coatings.

Together with our close business partners we are also able to deliver various NDT services such as Ultrasonic Tests, Eddy Current, Radiography, MPI, Dye Penetrant and Holiday Tests

Q: What is the most satisfying project that you have completed in the past two years and why?

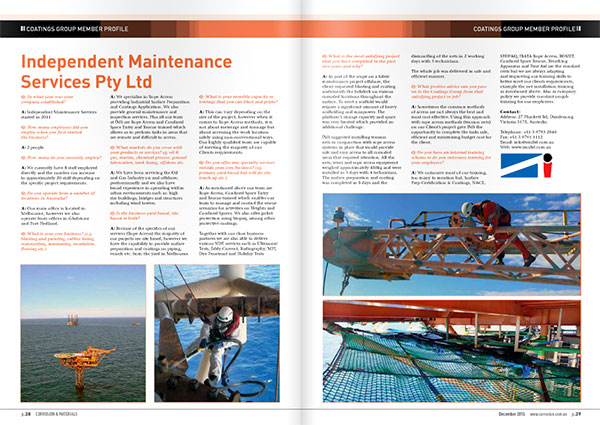

A: As part of the scope on a fabric maintenance project offshore, the client requested blasting and coating underneath the helideck on various corroded locations throughout the surface. To erect a scaffold would require a significant amount of heavy scaffolding and manpower. The platform’s storage capacity and space was very limited which provided an additional challenge.

IMS suggested installing tension nets in conjunction with rope access systems in place that would provide safe and easy access to all corroded areas that required attention. All the nets, wires and rope access equipment weighed approximately 450kg and were installed in 3 days with 4 technicians. The surface preparation and coating was completed in 5 days and the dismantling of the nets in 2 working days with 3 technicians.

The whole job was delivered in safe and efficient manner.

Q: What positive advice can you pass on to the Coatings Group from that satisfying project or job?

A: Sometimes the common methods of access are not always the best and most cost effective. Using this approach with rope access methods (tension nets) on our Client’s project gave IMS the opportunity to complete the tasks safe, efficient and minimising budget cost for the client.

Q: Do you have an internal training scheme or do you outsource training for your employees?

A: We outsource most of our training, too many to mention but, Surface Prep Certification & Coatings, NACE,

STOPAQ, IRATA Rope Access, BOSIET, Confined Space Rescue, Breathing Apparatus and First Aid are the standard certs but we are always adapting and improving our training skills to better meet our clients requirements, example the net installation training as mentioned above. Also as company policy we provide constant on-job training for our employees.

Contact: Address: 27 Plunkett Rd, Dandenong Victoria 3175, Australia

Telephone: +61 3 9793 2046 Fax: +61 3 9791 1112 Email: [email protected]

Web: www.imsltd.com.au

Source: Corrosion Magazine p.38-39